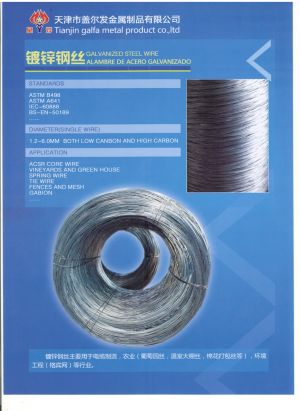

Hot - dipped galvaning is a process in which the wire is dipped in zinc to create a zinc coating. Hot - dipped galvanized steel wire has the advantages of corrosion resistance, good weather - resistance and long life, so it is widely used in many fields.

The requirements for hot - dipped galvanized steel wire are as follows:

1. Uniform galvanized layer: The galvanized layer of Hot - dipped galvanized steel wire should be uniform and dense, without defects such as uneven galvanizing, wrinkling, and falling off.

2. The thickness of the zinc layer is appropriate: the thickness of the zinc layer of the Hot - dipped galvanized steel wire should meet the standard requirements to ensure its corrosion resistance.

3. Good surface: The surface of Hot - dipped galvanized steel wire should be smooth, without obvious burrs and oxides.

4. Strong adhesion of galvanized layer: The galvanized layer of Hot - dipped galvanized steel wire should have good adhesion and not easy to peel off.

5. The chemical composition of galvanized steel wire is stable: the chemical composition of Hot - dipped galvanized steel wire should meet the relevant standards to ensure its quality stability.

6. The size of the galvanized steel wire is accurate: the diameter, strength and other dimensional parameters of the Hot - dipped galvanized steel wire should meet the standard requirements to ensure its performance.

In short, the requirement of Hot - dipped galvanized steel wire is to ensure that its galvanized layer has good quality and stable performance, so as to improve its corrosion resistance and life.

Main features

Multimedia

No reviews found